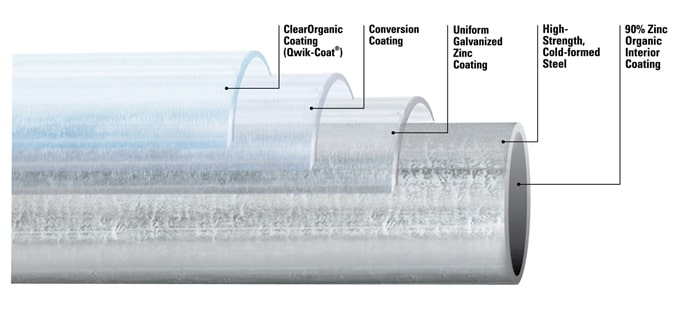

Allied’s Flo-Coat 50 galvanized steel tubing is the product of choice for carports and other portable buildings. The unique, in-line Flo-Coat process provides a triple layer of corrosion protection that stands the test of time.

The process begins with flat strip steel that is cold-formed and electric-resistance or induction welded. After welding, the tube goes through three coating baths.

The first coating bath bonds zinc to the hot tubing and is followed by a conversion coating. As the tube goes through the conversion coating bath, the process chemically changes the zinc already on the surface of the tube. The compounds that are formed make the zinc even less subject to corrosion than unprotected zinc. This conversion coating also provides another layer of protection for longer resistance to white rust corrosion.

The excess solution is then removed from the tube and the tube is dried to prepare for its third and final protective coating bath…an application of a clear organic polymer to give the tube superior corrosion resistance, added aesthetic appeal, and long-lasting surface brightness. This coating is then cured to a smooth, hard finish near the end of the in-line process. The result is a smooth, shiny end product appearance that is unmatched in terms of strength and durability – it will not oxidize or “gray down” with age, nor will the coating flake off during fabrication operations.

As you can see, the makes for a superior product for outdoor use. That’s why we choose Flo-Coat galvanized steel tubing for our structures.